Founded in 2005, C-Mac International specializes in the design and manufacture of advanced, tight-tolerance parts made from materials such as Alumina, Steatite, Tungsten, and Zirconia. As a leading Zirconia ceramic parts manufacturer, C-Mac creates finished components for a diverse range of industries, including:

- Aerospace

- Automotive

- Chemical

- Electronics

- Equipment & Machinery

- Food & Beverage

- Medical

- Nuclear Power

- Oil & Gas

- Refractory

We machine our own parts from special materials, which differentiates us from our competitors and improves our customers’ bottom line. With over 100 years of collective ceramics experience, the C-Mac International team works closely with you to deliver custom high-quality parts.

C-Mac’s Custom Manufacturing Capabilities

As a trusted OEM Zirconia ceramics manufacturer, C-Mac International excels in the design and manufacture of tight-tolerance custom ceramic components. We specialize in technical ceramic solutions made from Zirconia (Yttria and Magnesia stabilized), Silicon Nitride, Alumina (99.7% pure), and Tungsten Carbide.

Our products are engineered to withstand high temperatures and chemically harsh environments, providing exceptional wear resistance and durability. To shape the ceramic material and achieve tight tolerance and complex part configurations, we utilize the following processes:

- Dry Pressing

- Extrusion

- Green Machining

- Hot and Cold Forging

- Casting

- Injection Molding

- Slip Casting

Combining our expert ceramic formulation, design expertise, specialized machining and inspection equipment, and tight tolerance capabilities enables us to create critical-to-function components for a diverse range of industrial applications.

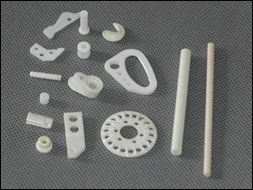

Zirconia Ceramic Applications

Zirconia (zirconium oxide ceramic) is an extremely hard and durable material that features flexibility, high strength, and low thermal conductivity. The material is often used to produce wear-resistant machine parts and components due to its toughness, chemical resistance, electrical insulation, and wear resistance.

With a higher melting point than Alumina, Zirconia is often used for technical applications such as:

- Ball valves

- Ceramic knives

- Knife sharpeners

- Grinding beads

- Dental implants

- Engineering parts (nuts and bolts)

- Mold inserts

- Oxygen sensors

- Pump seals

- Rods and tubes

- Transistor insulators

- Sintering plates

- Saggers

- Knee replacements and artificial joints

- Textile machine nozzles

Download Zirconia Technical Data Sheet

Zirconia Ceramic Properties

Corrosion Resistance

Zirconia ceramic components provide superior corrosion resistance against saltwater, alkalis, and acids, making them an ideal solution for applications in harsh environments that require:

- Exceptional longevity and performance

- Chemical inertness

- High temperature stability

- Minimal contamination

- Toughness and hardness

Abrasion Resistance

Zirconia ceramic components outperform many other materials due to the following properties:

- High toughness and hardness

- Low friction

- Self-lubricating

They are an ideal solution for applications such as bearings, industrial linings, and valve seats that rely on abrasion-free surfaces, particularly in high-temperature, harsh environments.

Chemical Resistance

Zirconia ceramic components feature excellent chemical resistance, being highly inert to most salts, alkalis, and acids. They are ideal for applications requiring chemical resistance to prevent degradation and maintain structural integrity in harsh, corrosive environments.

Strength & Hardness

Zirconia ceramic components exhibit high compressive strength and exceptional hardness, making them an ideal solution for high temperatures and extreme environmental conditions. They outperform many other ceramics and metals in impact resistance and durability. Due to its transformation-toughened capabilities, the structure of Zirconia transforms under stress, absorbing energy and preventing the spread of cracks—a feature not commonly found in other ceramic materials.

Zirconia Ceramic Component Manufacturing from C-Mac

As an industry-leading customized Zirconia ceramics manufacturer, C-Mac International offers efficient operations, quick response times, and low overhead. We are ISO 9001:2015 certified, designing and manufacturing high-quality, custom parts faster and at a 25% lower cost compared to large Tungsten and ceramics competitors.

Other competitive advantages include:

- 24-hour quoting

- Consignment programs

- Engineering expertise

- Material availability

- Prompt delivery

- Stocking programs

- Quick turnaround

Contact us today to learn more about our Zirconia ceramic components.